Why choose us?

COMPLETE SERVICE FOR METALWORKING

ENGINEERING SOLUTIONS

Our experienced and trained staff will find a solution for every need.

PRODUCT DEVELOPMENT

Whether it is individual or even standard parts, we produce it to the agreed deadline.

WHAT ARE WE DOING?

WE ARE LOCALS LIKE YOU, WE WORK WELL

Our company provides metal processing services, undertakes laser cutting, turning, milling, bending, welding, sandblasting and electrostatic painting of steel, stainless steel and aluminum parts with the help of professional equipment.

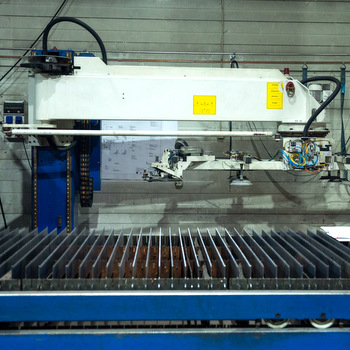

METALWORKING SERVICES

Our company undertakes laser cutting, turning, milling, bending, welding, sandblasting and electrostatic painting of steel, stainless steel and aluminum parts with the help of professional equipment.

We also undertake the fast and efficient delivery of the products to the customer's headquarters.

We also undertake the fast and efficient delivery of the products to the customer's headquarters.

DELIVERY TO THE PLACE OF ORDER AFTER MANUFACTURE

Technical equipment

What are we good at?

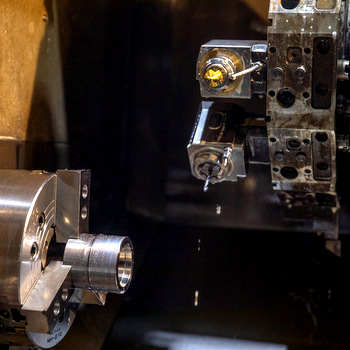

CNC turning

Turning is the technological operation of cutting a material with a lathe.

CNC bending

Precise bending of metal parts of different radii and grades and prototyping for new products.

CNC milling

Milling is the process of removing material by rotating tools by pushing the cutter into the workpiece.

Smoothing / blasting

This process removes rust and other contaminants from metal and degreasing.

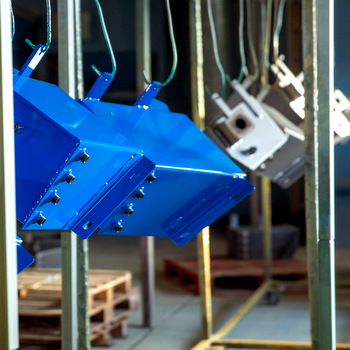

Electrostatic powder coating

Ideal for metal surfaces, provides long-lasting wear and tear resistance. This type of painting can also provide better smoothness of the paint layer, which means that the painted piece will end up looking flawless.

MIG/MAG welding

Electric arc welding process in a shielding gas medium with a melting electrode.

Painting of metal works

Applied technologies: shot blasting, electrostatic painting

Equipment parts

Applied technologies: cutting, turning, bending, painting, assembly

English (UK)

English (UK)  Deutsch (Német)

Deutsch (Német)  Română (România)

Română (România)  Hungarian (Magyar)

Hungarian (Magyar)