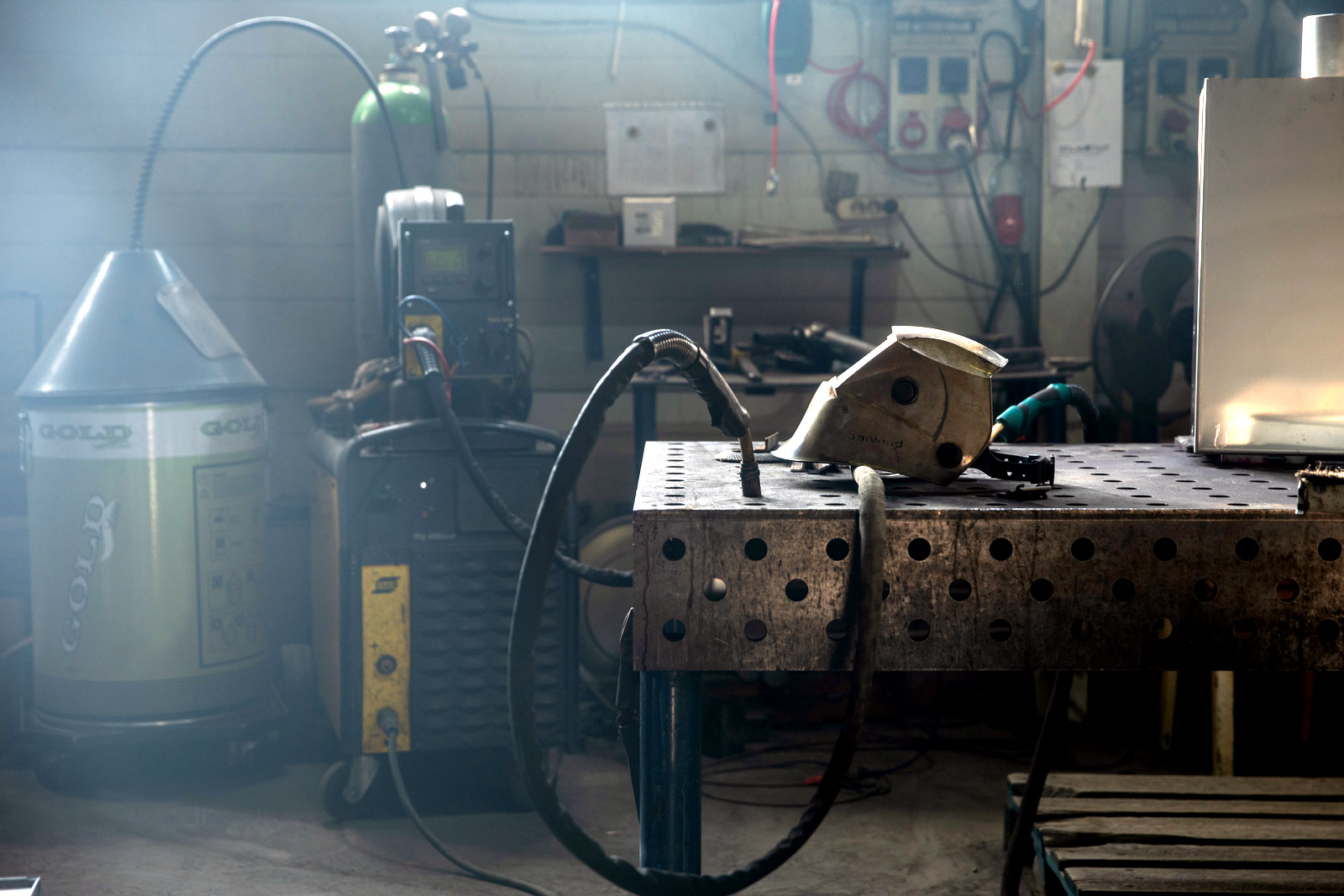

MIG/MAG = Metal Inert Gas Welding / Metal Activ Gas Welding

Sokan “CO hegesztésnek” hívják tévesen. A hozaganyag egy dobra feltekert huzal, amit a hegesztőgép adagol, ami lehet Szénacél, Alumínium, Bronz.

Védőgáz használata szükséges, ami lehet:

- tiszta CO2,

- CORGON (kevert gáz, Magyarországon 82% Argon – 18% Szén-dioxid),

- tiszta Argon, illetve

- rozsdamentes acél hegesztéséhez használatos CRONIGON 2, ami 98% Argont és 2% szén-dioxidot tartalmaz az ív stabilizálása érdekében.

A pisztolyon található gomb megnyomásakor gáz áramlik a gázterelőből, és hegesztőhuzalt a gép az áramátadón keresztül a hegesztendő anyaghoz tolja, ami rövidzárat okoz, és az ív létrejön a hegesztendő anyag és a huzal vége között. Mivel a huzal viszonylag vékony, ezért a gépnek folyamatosan adagolnia kell, hogy ne fogyjon el: innen kapta a nevét is: “fogyóelektródás hegesztés”.

Előnye: Gyors, termelékeny, nagyon könnyű megtanulni a hegesztést, vékony lemezek kiválóan hegeszthetők.

Hátránya: Költséges a védőgáz és a gép, ezért használata inkább az iparszerű munkáknál jellemző.

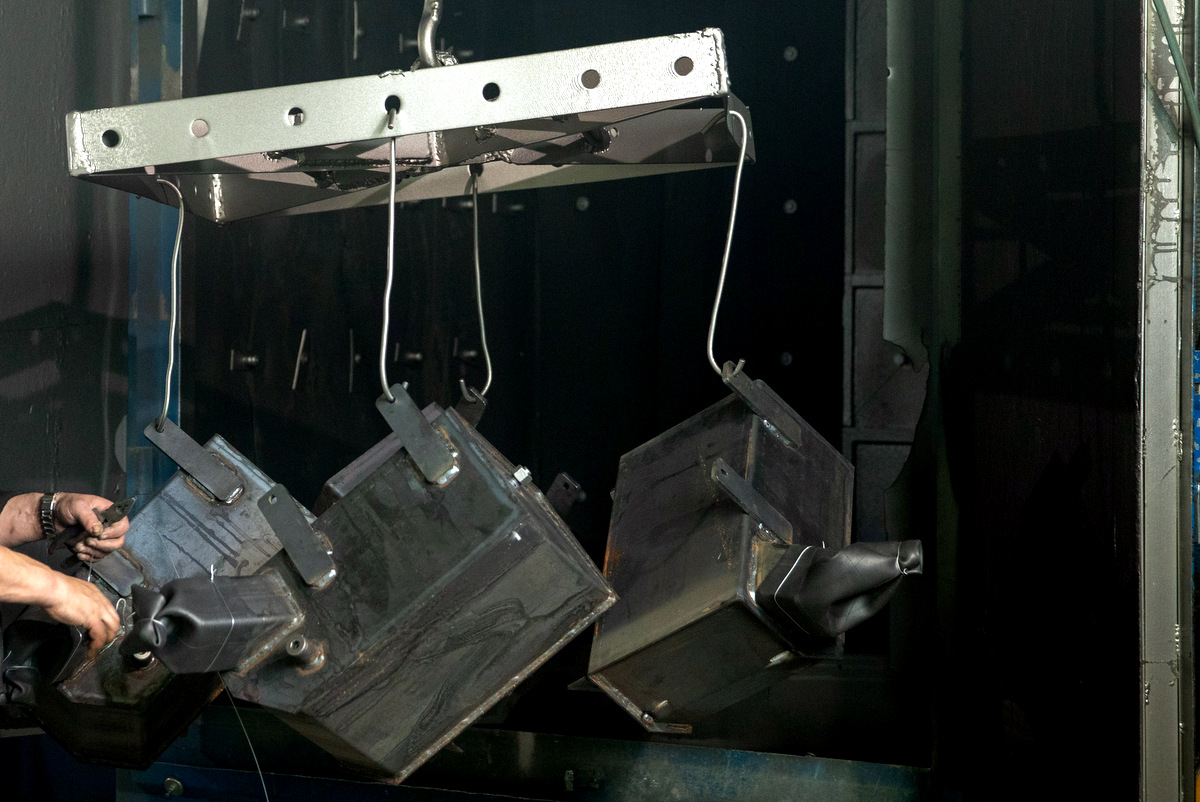

Electrostatic powder coating, also known as sintering, is a development of an earlier technology. The method is intended to make the coating more durable and a much more environmentally friendly process than solvent painting. The essence of the process is that the plastic is electrostatically charged, which is polyester or epoxy polyester, and the metal object attracts the plastic. The layer thickness can be controlled by the electrostatic powder spraying technique.

During powder coating, electrostatic powder spraying and sintering, the powder is charged and the workpiece is deposited. The metal actually attracts the toner. What does not adhere to the metal surface is usually sucked out by a suction device, which is separated by a cyclone and recycled, resulting in a lossless use.

English (UK)

English (UK)  Deutsch (Német)

Deutsch (Német)  Română (România)

Română (România)  Hungarian (Magyar)

Hungarian (Magyar)